Explore the Quiet Shift: How Modern Air-to-Water Systems Offer Quieter Heating in 2025

Roadmap and Why Quiet Heating Matters

Quiet often feels like a luxury until you compare two homes side by side: one humming with fans and vents, the other quietly maintaining warmth as if the building itself were breathing. The shift toward air-to-water systems in 2025 taps into that sensibility, replacing gusty airflows with the measured glide of heated water. This article is your guided tour of how and why these systems sound different, feel different, and can transform daily comfort without resorting to gimmicks or grand claims. Before we dive into details, here is the structure you can expect, along with what each part will deliver.

– Section 1 sets the scene and provides an outline, so you know exactly where you’re heading and why quiet comfort is not just a nice-to-have but a daily quality-of-life upgrade.

– Section 2 explains how liquid-based heat distribution minimizes temperature swings and drafty sensations, using the physics of water’s high heat capacity to spread warmth evenly.

– Section 3 looks at 2025 air-to-water heat pumps and their acoustic engineering, including why certain components can measure around 20–25 dB in specific tests, and what that means in the real world.

– Section 4 explores hydronic radiant systems and how they reduce mechanical noise by removing blowers and big ducts, replacing the whoosh with a gentle, background hush.

– Section 5 ties it all together with practical design tips, selection pointers, and a homeowner-focused conclusion that helps you turn theory into a plan.

This roadmap matters because sound is not just volume; it is a texture that colors your routines. Low-frequency fan drone can be tiring, while intermittent blasts can interrupt sleep or concentration. Conversely, a hydronic circuit circulating tempered water can feel almost invisible. The difference shows up in subtle ways: fewer abrupt on-off cycles, more stable room temperatures, and the sense that walls and floors are radiating quiet confidence. If you are planning a renovation, building a new home, or updating mechanical systems in a small multifamily property, the following sections will equip you with concepts you can bring to your designer or installer. Expect clear comparisons, data-informed context, and small design choices that have big acoustic payoffs.

Why Liquid-Based Heating Feels Steadier Than Blown Air

Liquid-based heating delivers a kind of steadiness that is hard to replicate with ducts and fans. The difference begins with physics: water’s volumetric heat capacity is over three thousand times greater than that of air. That means a relatively small volume of water can carry a substantial amount of heat at modest temperature differences. When you circulate that energy through panel radiators, fanless convectors, or in-floor tubing, the building surfaces become part of the distribution system. Instead of sudden gusts followed by cool lulls, you get a calm, near-continuous release of energy that keeps the mean radiant temperature more consistent.

For occupants, that steadiness translates to comfort at slightly lower air temperatures because the surrounding surfaces are warmer and the body loses less heat by radiation. If you have ever stood near a window on a cold day and felt chilled despite a high thermostat setting, you’ve felt the opposite effect. Hydronic emitters help counter that by elevating surface temperatures, reducing stratification and cold spots. And because there is no high-speed air movement across your skin, the space avoids the “wind chill” sensation that some forced-air systems can create during heat calls.

Humidity balance is another quiet win. Without large volumes of heated air whisking through supply registers, there is less tendency for indoor humidity to drop precipitously in winter. Rooms feel less parched, wooden furniture is less prone to shrinkage, and musical instruments or art can live in more stable conditions. Hydronic systems also avoid the dust and allergen recirculation associated with ducts, which can be beneficial for sensitive occupants. None of this requires extraordinary technology; it is simply a result of using water as the energy carrier and letting building materials act as gentle buffers.

Practical examples make the benefits tangible. Imagine a living room with radiant flooring operating at water temperatures in the 30–45°C range (approximately 86–113°F). The slab or panel warms slowly, then coasts for long periods with only a whisper of circulation pump activity. A well-sized panel radiator in a bedroom can do the same, offering a soft envelope of warmth without waking a sleeper with fan noise. And because many modern controls modulate water temperature with outdoor reset, the system further reduces on-off cycling, smoothing the thermal profile hour by hour. The result is not theatrical; it is simply the kind of comfort you stop noticing because it feels natural.

– Water carries high heat content at low flow rates, reducing rapid temperature swings.

– Radiant and panel emitters raise mean radiant temperature, allowing lower air temperature for equal comfort.

– Lower air movement cuts drafts and reduces airborne dust.

How 2025 Air-to-Water Heat Pumps Achieve Whisper-Quiet Operation

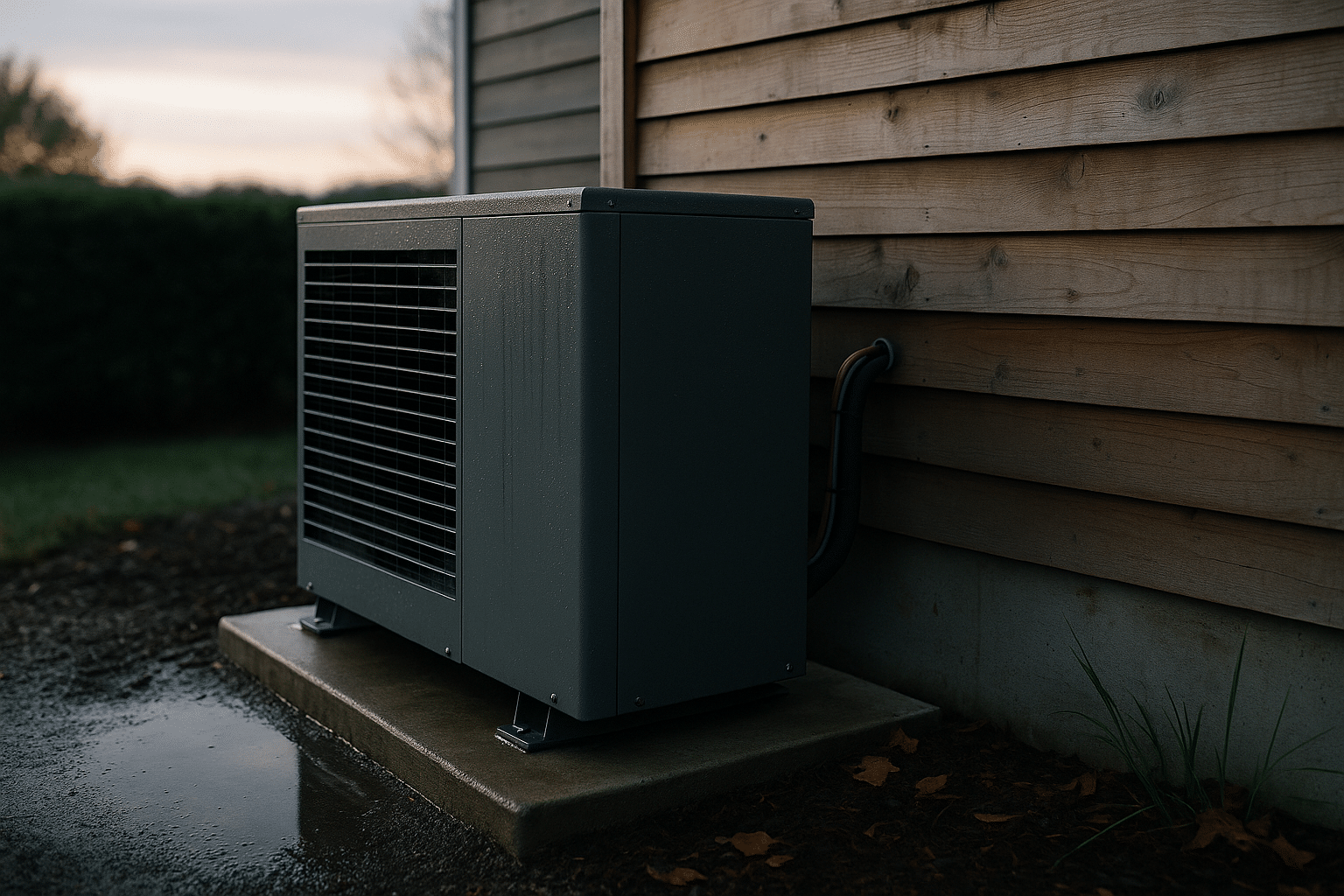

When people hear “heat pump,” they often picture a fan outside and a utility room humming inside. In 2025, air-to-water units have been refined with acoustics in mind, making that picture noticeably quieter. Key strategies include variable-speed compressors and fans, large-diameter slow-spinning blades, advanced inverter drives that avoid harsh tonal peaks, and cabinet designs with decoupled panels to damp vibration. Inside, circulation pumps with ECM motors run at lower speeds most of the time, and decoupling mounts help isolate structure-borne noise. Together, these solutions reduce both sound pressure levels and the kinds of tones the ear finds distracting.

It is important to anchor terms. Sound is measured in decibels, and decibels are logarithmic. A 10 dB increase sounds roughly twice as loud to most listeners, and doubling the distance from a point source reduces the measured level by about 6 dB in free field conditions. Manufacturers publish sound data in different ways: some list sound pressure levels in dB(A) at a certain distance, others provide sound power levels that are independent of distance. Under specific laboratory conditions—typically partial-load operation, low fan speed, and controlled background noise—some components can register around 20–25 dB(A). That is comparable to a very quiet room or rustling leaves, but remember that real installations include reflections, background noise, and load changes.

Context keeps expectations realistic. An outdoor unit during defrost or peak output will be louder than during mild, steady operation. Indoor hydro modules may include pumps and valves that click or whirr when they change state. The takeaway is not that a system is silent, but that with thoughtful design, most operation happens in a range that fades into everyday background sound. Practical steps make the difference:

– Place outdoor units away from bedroom windows and at corners that minimize line-of-sight to sensitive spaces.

– Use vibration isolators under the base and flexible connections to avoid structure-borne transmission into the building.

– Size emitters generously so the unit can run at lower fan and compressor speeds, which are typically quieter and more efficient.

– Add modest acoustic screening where appropriate, ensuring airflow remains unobstructed.

Finally, verify data carefully. Look for standardized test references, note whether figures are sound power or sound pressure, and ask for the distance and environment used for measurement. A unit that lists 20–25 dB(A) for a specific component in a lab does not guarantee the same level on a windy night near a reflective wall. Still, the direction is clear: modern air-to-water systems manage sound with a combination of component design and operating strategy that keeps most of their work in the “whisper” bracket for much of the season.

Hydronic Radiant Systems and the Vanishing of Mechanical Noise

Hydronic radiant systems remove an entire category of sound by design. There are no large blowers, no sheet-metal ducts acting as soundboards, and no register whistles when someone closes a door. The primary mechanicals become small circulators and mixing or zone valves tucked into a utility closet or mechanical room. When the distribution is a slab or a low-profile panel system, the emitter itself has no moving parts. The result is a background acoustic signature that is more like a refrigerator at idle than a conventional furnace cycling with a fan.

That does not mean every hydronic system is automatically quiet. Water moving too fast through undersized tubing can hiss, and poorly isolated pumps can transmit vibration to framing. Step one is thoughtful hydraulics: target moderate flow velocities, balance loops, and use variable-speed pumping so the system supplies only what the zones need. Careful pipe supports with rubber isolation, air elimination to prevent micro-bubbles, and a well-sized expansion tank all help remove incidental noises. Expansion and contraction in radiant slabs or panels can create faint creaks if temperature changes are abrupt; gentle temperature ramps and outdoor reset controls mitigate this.

Radiant designs also reduce sound from airflow itself. Without ducts, there is no pressure network to leak, boom, or drum. Rooms lose the “wind events” that can rattle blinds or draw attention to dust on windowsills. The remaining noise sources are usually service events you hear only up close: a relay click at a control panel, a soft valve actuation, or a circulator starting at low speed. With proper commissioning, those events are brief and infrequent, and the steady-state condition is near silence.

Beyond acoustics, radiant hydronics shape comfort in ways that further reduce the urge to “chase” the thermostat. Surfaces at slightly higher temperatures mean fewer drafts from convective loops around windows, and furniture feels usable in more parts of a room. That less frantic interaction with controls is itself an acoustic win, because it keeps mechanicals in a stable operating envelope. Consider a retrofit scenario: pairing low-temperature panel radiators or underfloor panels with an air-to-water unit lets you run supply temperatures low, trims cycling, and leverages thermal mass for long, quiet intervals. The quiet becomes part of the room’s character, like good light or a solid door close.

– Keep water velocities moderate to avoid hiss and valve chatter.

– Use outdoor reset to avoid abrupt temperature swings and expansion creaks.

– Isolate pumps and piping to prevent structure-borne vibration.

Conclusion: What Quiet Comfort Means for Homeowners and Designers

Putting it all together, air-to-water heat pumps and hydronic distribution offer a practical path to a home that sounds and feels calmer. The physics favor smooth delivery: water carries heat gently, surfaces release it evenly, and modern components modulate rather than slam between off and on. For homeowners, that means rooms where conversation is clear, sleep is less interrupted, and winter air does not feel parched. For designers and installers, it means aligning acoustics, efficiency, and comfort in one integrated plan rather than treating noise control as an afterthought.

Translating concepts into a project starts with a few high-impact moves:

– Choose emitters sized for low water temperatures to keep compressors and fans at quieter operating points.

– Place outdoor units and indoor hydro modules thoughtfully; avoid reflective corners and shared bedroom walls where possible.

– Use vibration isolation, flexible connectors, and acoustically aware mounting details.

– Commission carefully: balance loops, purge air, confirm pump speeds, verify outdoor reset, and document target sound levels in key rooms.

Set expectations with data. Aim for bedroom nighttime sound pressure levels that blend with background, often in the mid-20s to low-30s dB(A) range depending on the site. Understand that published 20–25 dB figures typically reflect specific components at partial load in controlled tests, not a whole-system guarantee in every condition. The value lies in how frequently the system can operate in that quiet bracket, which is largely a function of emitter sizing, control strategy, and installation quality.

If you are upgrading from a furnace with high-speed ductwork, the change can feel subtle at first, then unmistakable: fewer abrupt cycles, softer temperature gradients, and a background soundscape that recedes. In new construction, integrating hydronic radiant floors or generously sized panel radiators from the outset delivers an acoustic dividend for decades. Either way, the move toward water-based distribution and modern air-to-water technology is not just about efficiency curves; it is also about the everyday soundtrack of your home. Choose components with transparent acoustic data, plan the layout with sound in mind, and let the building do the quiet work of staying warm.